Due to its inherently low volumetric energy

density, hydrogen produced via water electrolysis must be densified and stored

in alternative forms. Principal storage pathways—including liquid-organic

hydrogen carriers (LOHCs), cryogenic liquefaction, and high-pressure

compression—are commonly integrated into hydrogen refueling station.

Collectively, these storage and logistics chains are poised to underpin

large-scale hydrogen transport and storage, thereby becoming a critical enabler

of the emerging hydrogen economy.

Our laboratory research on:

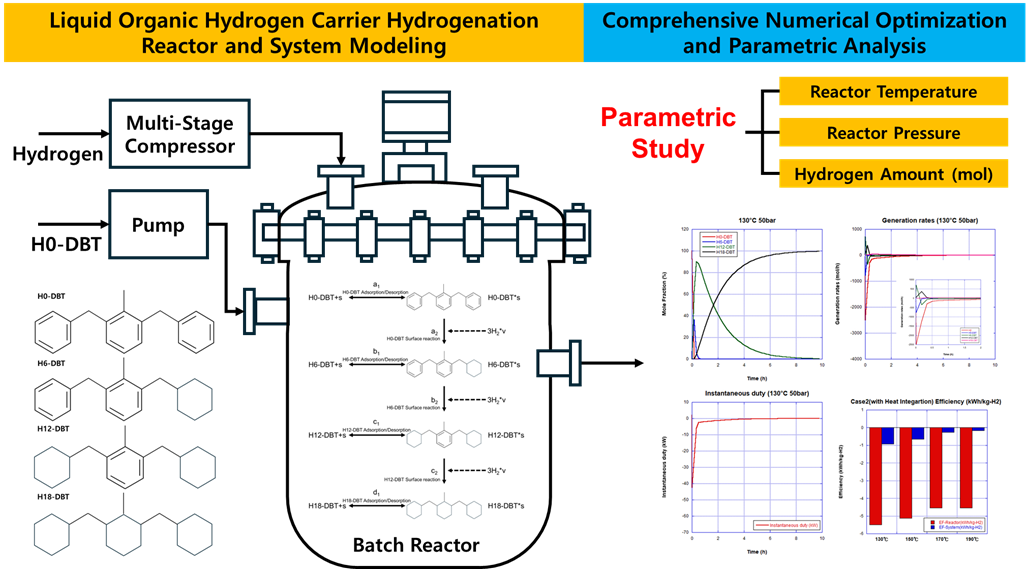

Liquid Organic Hydrogen Carrier System

The Liquid Organic Hydrogen Carrier (LOHC) system stores and transports hydrogen by reversible hydrogenation and dehydrogenation of organic liquids like dibenzyltoluene. System design involves integrating electrolyzers, hydrogenation/dehydrogenation reactors, and heat management units to maximize efficiency. Research focuses on Reactor Modeling, thermal integration, and operational stability for large-scale applications. LOHC systems offer high hydrogen storage density and are promising for sate, efficient grid-scale energy storage.

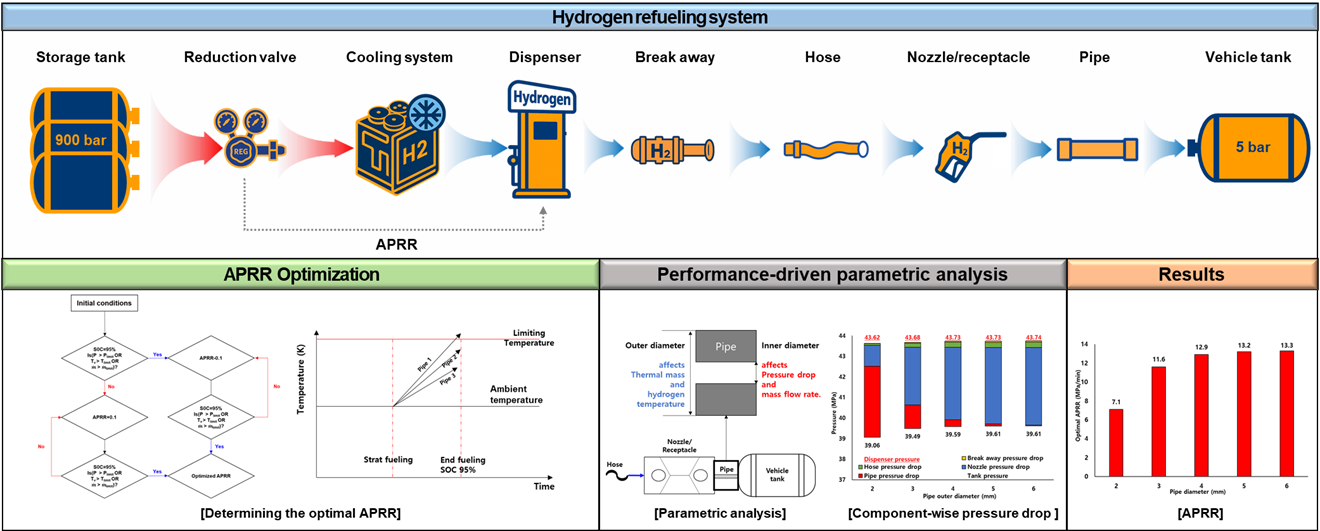

Compressed gas hydrogen refueling system

Hydrogen refueling systems predominately use compressed gaseous hydrogen. High-pressure gas stored in cascade cylinders is dispensed to vehicles; however, operating at such pressures involves considerable mechanical complexity, and the electricity required for compression and precooling accounts for major share of station operating expenses. Consequently, current research prioritizes system-level optimization-while carefully taking safety considerations into account-to reduce these energy demands and to develop advanced despensing protocols that enable rapid filling while minimizing compressor and chiler power use. Future studies are expected to focus on cryogenic liquid-hydrogen refueling architectures and on-site electrolyric hydrogen production technologies-such as alkaline, PEM, AEM, and SOEC-to further reduce costs and enhance operational flexibility.

Our laboratory will advance hydrogen storage and utilization research through an integrated, modeling-based approach.

1. Integrated Storage and Utilization System Design

Performance characteristics will be modeled across multiple storage pathways — compressed gas, cryogenic liquid, LOHCs, and others — under a range of operating conditions. A multi-objective design methodology will then be developed to optimize energy efficiency, cost, and component durability.

2. Dynamic System Modeling and Operational Strategy

Physics-based and data-driven simulation tools will be employed to construct a digital twin of the hydrogen storage system that captures its transient behavior. This model will yield optimal control strategies that minimize energy consumption while maintaining stable, high-performance operation.

3. Economic Feasibility and Policy Analysis

Techno-economic models incorporating key parameters — such as storage method (liquid hydrogen, high-pressure gas, or cryo-compressed) and operating conditions — will be developed to evaluate the economic viability of the hydrogen economy and to identify effective policy support measures. Collectively, these studies aim to accelerate the deployment of optimized hydrogen energy systems, contribute to carbon neutrality, and provide practical solutions for related industries.